Environment

The NIKKOL GROUP recognizes that protecting the global environment is a shared challenge for all humankind and

strives to manufacture products with low environmental impact.

We proactively improve our manufacturing

processes and have them evaluated by third-party organizations to conserve energy.

In addition, we are

working to effectively use resources, for example, by reducing and reusing waste, to address the resource issues

that arise through our business.

As a specialty company, we strive to promote responsible environmental

management throughout the Group.

-

CO2 emission reduction targets

and emissions monitoring -

Aiming for zero CO2 emissions from

electricity at three domestic factories -

Energy-saving

DO (dissolved oxygen) meters - Eco-Action 21

- Solar power generation

-

Energy efficient

gas cogeneration -

Reducing environmental

impact at overseas factories -

ZEB Ready (An energy-saving

system for buildings) -

Environmentally friendly

manufacturing - NIKKOL ECO ACTION

-

Reusing water and

wastewater treatment -

Using environmentally

friendly materials - Reusing rainwater

Initiatives to Reduce Environmental Impact

CO2 emission reduction targets and emissions monitoring

The Paris Agreement came into force in 2016, setting a goal of limiting the rise in average temperatures to 1.5°C compared to pre-industrial levels. Japan has also announced a 46% reduction in greenhouse gas emissions by 2030 (compared to 2013), and is considering making it mandatory for Prime-listed companies to disclose emissions, indicating calls for action at a national level. The NIKKOL GROUP has set a CO2 emission reduction target of 30% in the Manufacturing Division and 15%–25% in other divisions (compared to FY2019) by FY2025 and monitors CO2 emissions at each group company every month to promote reduction activities.

Aiming for zero CO2 emissions from electricity at three domestic factories

In October 2023, Nippon Surfactant Industries’ Utsunomiya and Nasu factories and the Nasu Factory of Bergerac Japon switched to CO2-free electricity,* resulting in zero CO2 emissions from electricity. This switch will decrease approximately 2,752 tons of CO2 per year (compared to 2019). *The Green Basic Plan provided by TEPCO Energy Partner, Inc.: A plan that is compatible with RE100, combining the average power of all power sources with FIT non-fossil certificates (with tracking) and non-FIT non-fossil certificates designated for renewable energy (with power source attribute information).

Energy-saving DO (dissolved oxygen) meters

Nippon Surfactant Industries is changing the equipment installed in its factories to energy-saving electric motors that have a smaller environmental impact, and is also actively promoting inverter control. In addition, lighting equipment is being switched from fluorescent lights to LEDs. One example of inverter control is the blower at the wastewater treatment plant, which consumed a lot of electricity during 24-hour continuous operation. By installing a DO (dissolved oxygen) meter at the wastewater treatment plant and inverter controlling the blower based on the DO (dissolved oxygen) value, the blower output can be adjusted according to the amount of oxygen required, reducing unnecessary power consumption and promoting energy conservation.

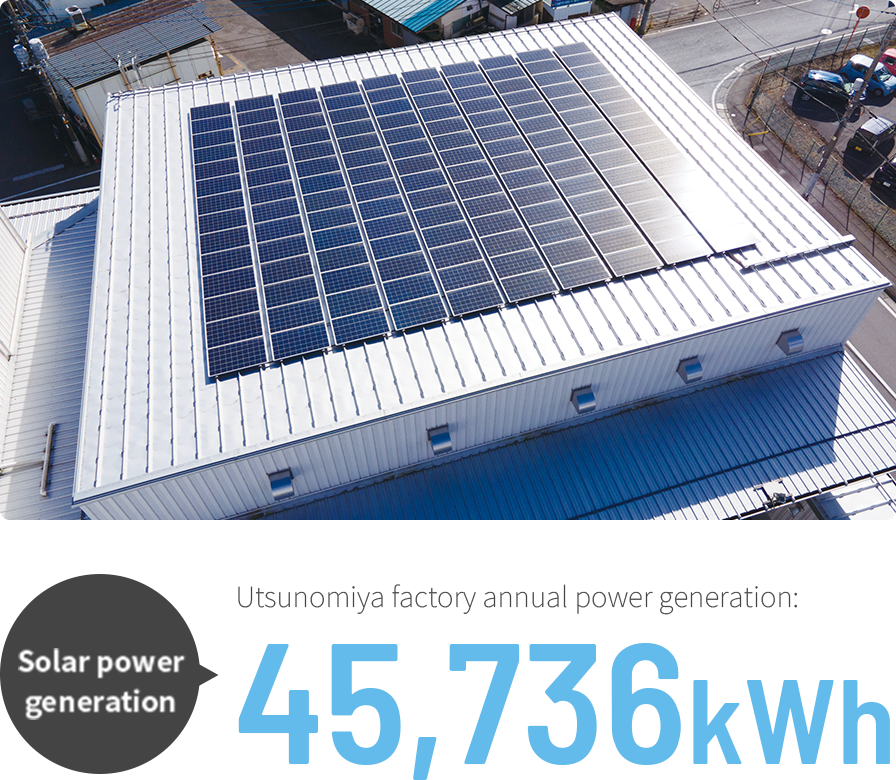

Solar power generation

Nippon Surfactant Industries’ Utsunomiya and Nasu factories use electricity generated by solar power. The annual power generation in Utsunomiya is 45,736 kWh (actual results for FY2021, approximately 0.8% of purchased electricity), which is equivalent to the amount used in logistics buildings. The solar power generation system will be expanded in Nasu in 2024, with a maximum power generation of 600 kWh, which will cover approximately 30% of the electricity used throughout the site. We will continue to promote the use of renewable energy in the future.

Eco-Action 21

Eco-Action 21 is a unique Japanese environmental management system established by Japan’s Ministry of the Environment. Companies that adopt the system are required to improve the environmental performance of the products they produce, sell, and provide, and to improve their services. The results of these efforts are annually published in an environmental management report. Nippon Surfactant Industries has acquired this certification every year since 2012, and in August 2021, the company was recognized by the Eco-Action 21 Central Secretariat as a “certified permanent business.”

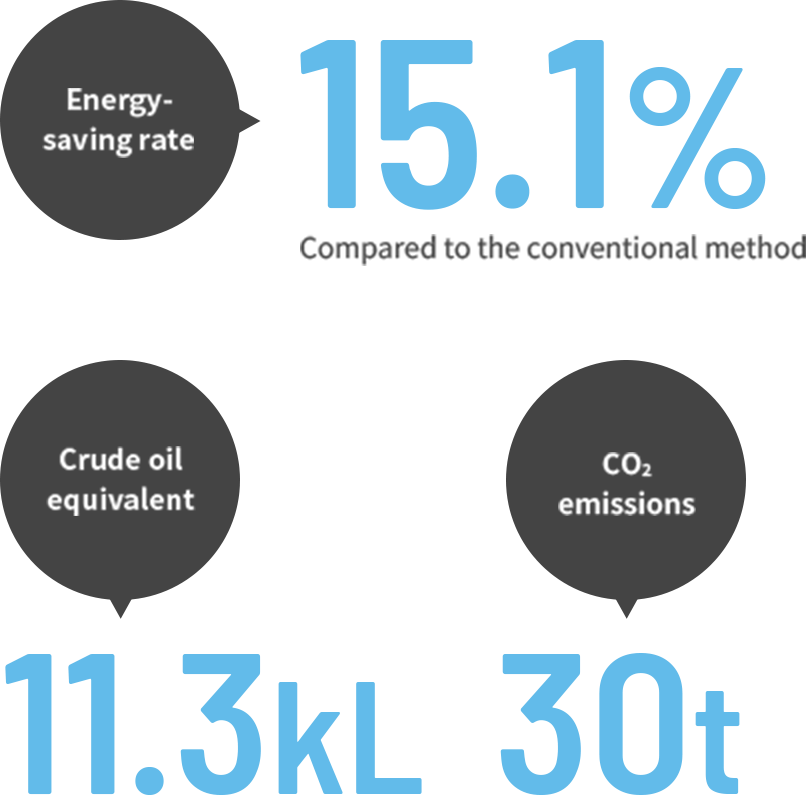

Energy efficient gas cogeneration

Nippon Surfactant Industries’ Utsunomiya factory has installed a gas cogeneration system. The electricity produced by this system is used for in-factory processes, and the heat is used for the water supply’s steam boiler. The use of the cogeneration system has achieved an energy saving rate of 15.1% (compared to conventional systems). This has reduced 11.3 kL/year in crude oil equivalents and approximately 30 t/year in CO2 emissions. (Installed in 2015)

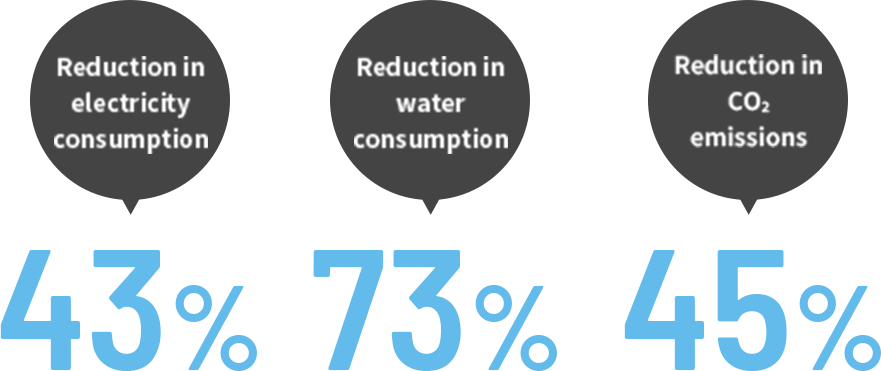

Reducing environmental impact at overseas factories

Nikko Chemicals Singapore has optimized its operations by shutting down the cooling tower every time production is finished. The cooling tower was previously in operation 24 hours a day, so this measure has reduced electricity usage by 540,000 kWh (43%), water usage by 18,000 m3 (73%), and CO2 emissions by 250 tons (45%) per year.

Initiatives to Reduce Environmental Impact|R&D

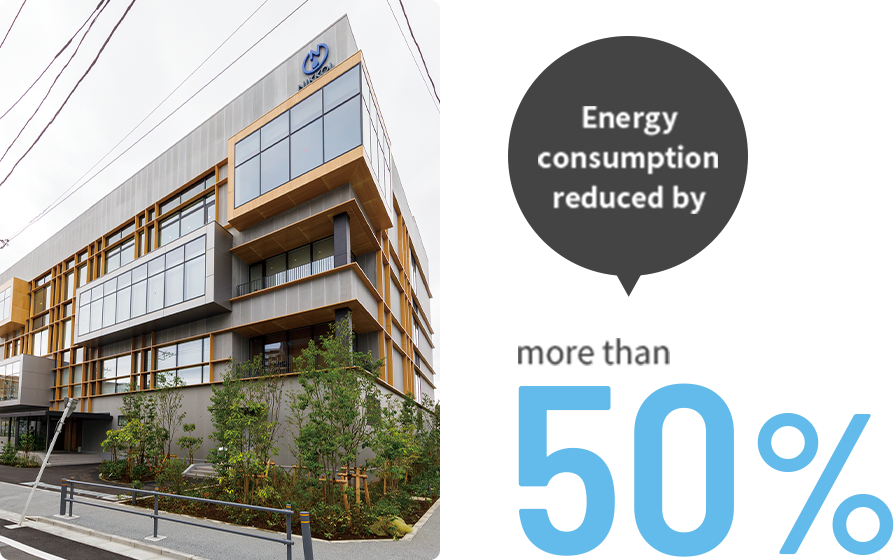

ZEB Ready (An energy-saving system for buildings)

ZEB (Net Zero Energy Building) is a certification system for buildings that are constructed with the aim of achieving both a comfortable indoor environment and energy conservation. The Nikko Chemicals R&D Center was rebuilt in 2022 as an energy-saving laboratory. The building has been certified as “ZEB Ready” through an external evaluation by BELS (Building Energy Efficiency Evaluation System), and has reduced the energy required to less than 50% of the previous level.

Environmentally friendly manufacturing

Nikko Chemicals has been working for many years on environmentally friendly manufacturing by applying bioengineering. We are devising bio-based technologies by applying fermentation technology using microorganisms, developing original enzymes, enzyme reaction technology, and other initiatives. In another example, we have been participating in the MATSURI Project* as a corporate partner since August 2022. We are working with various companies and governments from a wide variety of industries to develop sustainable products using algae. *The MATSURI Project is a Japanese corporate collaboration project using algae.

Effective Resource Use

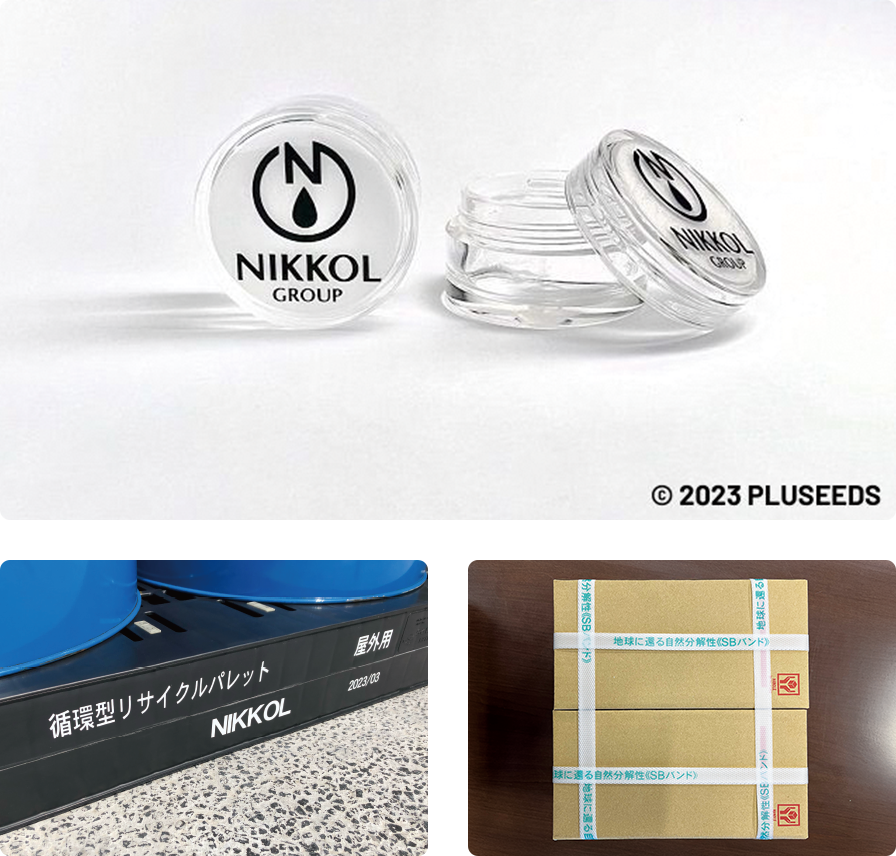

NIKKOL ECO ACTION

To contribute to the realization of a sustainable society, Nikko Chemicals devised its NIKKOL ECO-Friendly Policy, and has been implementing NIKKOL ECO ACTION since 2023 as a measure to reduce industrial waste by shipping and selling products with only minor damage to the exterior or container of the product and that meet the existing quality standards.

Reusing water and wastewater treatment

At Nippon Surfactant Industries’ Utsunomiya factory, we have introduced water recycling equipment in some processes carried out within the facility. In addition, by installing a 1,4-dioxane removal device in the wastewater treatment process, we are achieving the target values and are working to reduce our environmental impact. This device is the first of its kind used by a private company in Japan that can treat industrial wastewater, and it is also the first in Japan to use a multi-stage series system (excluding experimental models). We strive to protect the environment by reusing water and reducing wastewater from the facility.

Using environmentally friendly materials

Sample container, pallet, cushioning material, bundling band, shipping markWe actively use environmentally friendly materials not only in our manufacturing processes for sample containers, pallets, cushioning materials, cable ties, and shipping marks, but also in the various materials we use in our business. Starting in 2023, when holding expos and promoting sales to customers, Nikko Chemicals’ Personal Care International Business Unit uses formulation sample containers made from intermediate resins that were previously discarded. Starting in 2023, Nippon Surfactant Industries has also turned its attention to reducing its environmental impact on the ocean by introducing OBP (Ocean Bound Plastic) pallets made from recycled plastic waste that would otherwise present a high risk of leakage into the environment. In addition, the cushioning materials and cable ties used to transport products and samples are highly biodegradable.

Reusing rainwater

At Bergerac Japon, we flush toilets using rainwater collected in an underground rainwater storage tank. Rainwater runs down the roof of the factory through gutters and is stored in the tank, where it is passed through a rainwater treatment filtration system to remove impurities so that it can be used as flushing water. By using this rainwater to flush all the toilets at Factories 1 and 2 at Bergerac Japon, we are contributing to reducing the amount of tap water used.

More CSR activities

Find out more about what we do in other CSR categories.